Pinpoint Metal Art

Greg and Kelly Gillis use their CNC plasma cutter to make the most delightful products

Pinpoint Metal Art’s workshop smells like woodsmoke, hot oil and the air after a thunderstorm. Their big, high tech CNC (Computer Numerical Control) plasma cutter is the first thing you see walking in and the focal point of their work together. Their CNC plasma cutter uses 220, single phased power with 90-100 pounds air pressure to cut through metal. Partially finished projects and prototypes like a mosquito repellant egg carton burner, garden stakes and sunflower ornaments adorn the workbench and walls.

Kelly and Greg Gillis are the husband and wife team behind Pinpoint Metal. “I do all the computer work,” Kelly says, “and Greg does all the finishing, the welding and the painting and everything.” They use their CNC cutter to transform sheet steel and aluminum into ornaments, signs, wall clocks, fire pits, shelves and a whole range of custom made items.

The well organized roomy space also houses a paint room, auto body repair equipment, huge metal tool boxes, retro posters, a huge music speaker with changing coloured lights and a wood stove to keep it all cozy. And it has a ceiling high enough to hoist a car up on the hydraulic lift.

Their grey and white kitty, Lugnut, made us feel welcome with a brief visit when we arrived.

The 2,200 pound machine in the room

But the machine dominates the room. It’s built around a 4 by 4 foot table with what looks like a massive bicycle chain running over the top. Greg assembled the 2200 pound, $35,000 machine himself. He says, “I always wanted something like this. It was a big leap…it’s a beautiful machine.” Kelly adds, “We decided to go with this machine because it’s Canadian made and the support is Canadian.” The model they went with is a product of Fab-Cut Systems.

When they fired it up while we were there, it was loud and sounded like what I can only describe as a gargling dragon. And it was bright. You could not look at the plasma stream without dark glasses on, but it cut out a garden stake with a delicate design in a matter of minutes. Powerful.

The design process

They do a lot of custom work, but a lot of the original ideas are Greg’s. Kelly say he has so many, she is constantly telling him to put them in their idea book. She says, “Greg has the ability to see things and how we can do it.”

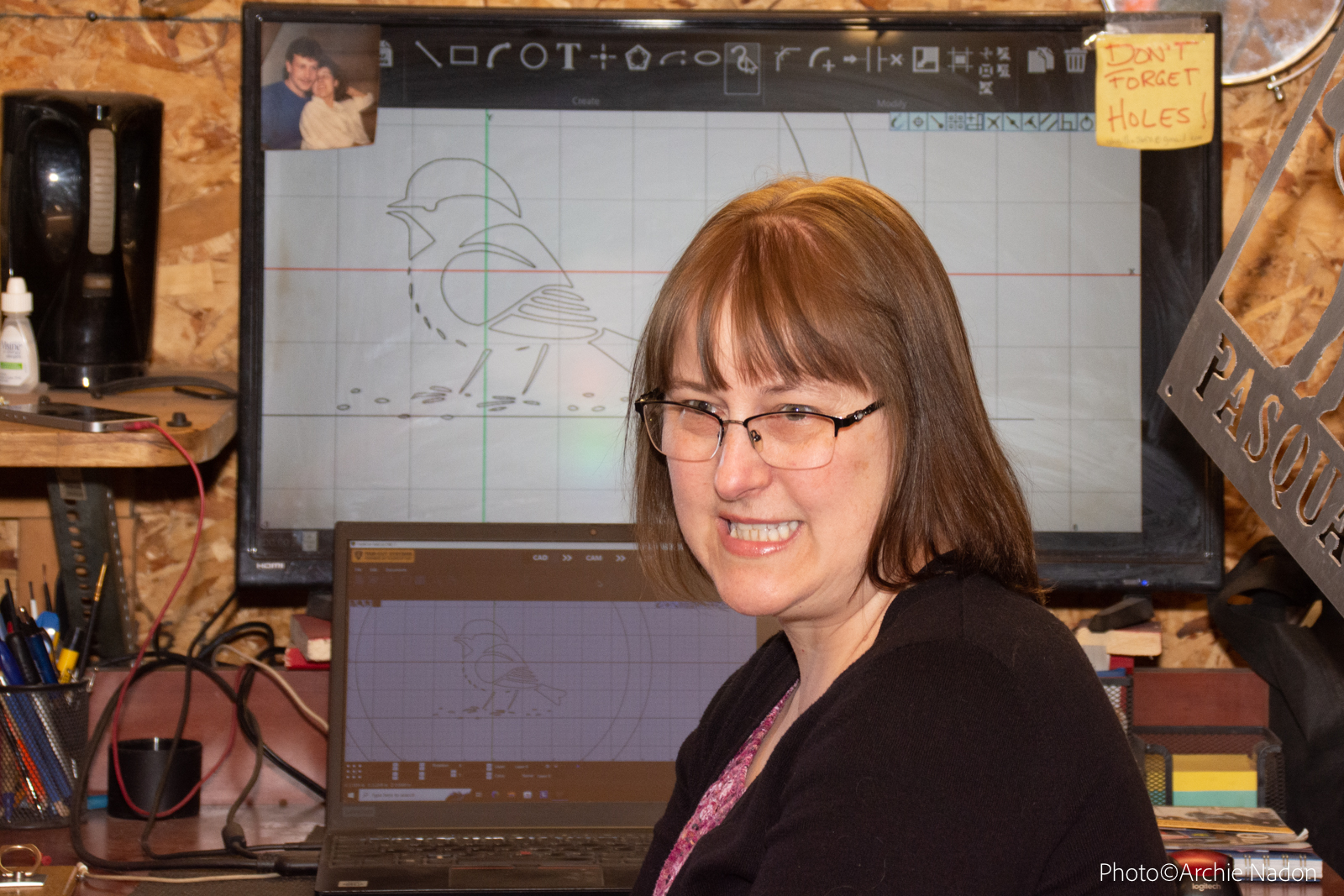

Kelly translates Greg’s ideas into designs and programs them into their Computer Aided Design (CAD) program which she taught herself to use. They threw around a lot of acronyms like CAT, CAM and CNC which translated to Computer Applications Technology, Computer Aided Manufacturing, Computer Numerical Control, respectively, when discussing their machine.

It’s pretty high tech and Kelly’s job of programming instructions for cutting is critical. “I am not what they call CAD trained,” she says. “I just knew how to operate a computer. We just got the program and I basically taught myself.”

She starts her design process with downloaded clip-art to use as an outline but makes original compositions from the various elements. She explains that in designing the lines for plasma cutting, “everything has to be connected” or it will fall apart.

And there are the hanging holes. There is a cardboard sign written in red marker that says DON’T FORGET THE HOLES! taped to her computer. She says,“I have a tendency to forget to put the hanging holes.” Without the hanging holes, the piece can’t be mounted anywhere.

She says she would like to up her design skills by trying her hand at freehand drawing. “I have been looking for something on the iPad because I have a pencil that I could draw with and I could import that into this program.” This would allow her freedom to do original drawings.

Greg’s metal skills

After the patterns are cut, Greg’s auto body painting skills come into play. He cleans and sands the pieces and then takes them to his paint room for a perfect finish. He’s a member of the Painters Allied Trades Union and started out in auto body, later branching out into commercial coatings and sandblasting. His other skills include welding, carpentry, diesel automotive, machining. He says, “There’s not too much I haven’t done.” He loves to make things and seems to keep learning the skills to help him expand his repertoire.

Products

Seasonal items are big sellers and they were working on Mothers Day items and garden accessories while we were there. Some of their other popular items include: tea lights, garden markers, floating shelves, monogrammed items, civic numbers, 3-D sculptures and durable customized estate signs finished with epoxy paint.

Custom orders make up a lot of their work. Kelly says she was recently asked, “Can you do a fiddle?” And they did. And they even made a specially ordered fireplace insert for a neighbour. “But monograms are the biggest thing,” Kelly says, “something that we do over and over again. People want them for gifts.”

Most of their products now are made of aluminum. They started out using steel. “And then COVID happened,” Kelly says. “The price of steel skyrocketed and Wilf’s Demolition (their local supplier) had a supply of aluminum and we tried it.” It turned out to be a bonus because the steel was prone to rusting and required more preparation. Aluminum has no such problems.

Where do they sell?

They have sold in local markets like the Saturday Artisan’s Market (S.A.M.) in St Peters and the Antigonish Farmers Market. Now they hope to get into the Mabou Farmers Market next.

They have been grateful for the support of two local restaurants in Port Hawkesbury, the Fleur de Lis Tea Room and Dining Room and the BaRyKin Cafe and Bakery who display and promote their work.

Kelly says that aside from Facebook, “We haven’t done any advertising.” Word of mouth is invaluable, as they are very connected to their community and they will also barter to support their neighbours. They haven’t needed any advertising because they are working at the pace they want. She’s still working at her weekday job and only works at the business on weekends, which includes going to markets.

What’s next

What are they working on next? Greg is most excited about creating a metal rolling machine for making big round fire pits with decorative cutouts, like monograms or a silhouette of your dog. Also, Kelly adds, “We’re trying to develop something that would be backlit that may interest some people.” It’s a wooden frame with a light behind a metal cutout for signs or sayings. The CNC cutter obviously fuels their imaginations. Kelly says,“We get really excited when we have a new design.”

Kelly’s business philosophy is slow and steady. “We’re a small company. We’re growing at the pace that is right for us,” she says. “Other than the CNC machine we haven’t gone into debt to do this. We wait till we have sales and buy what we need to buy. We want to make it sustainable.”

Author details

Elaine Mandrona, in addition to being a writer, is a painter and sculptor. She moved to Cape Breton permanently in 2021.